BMW Bridge Munich 48°10'37.1"N 11°33'27.0"E

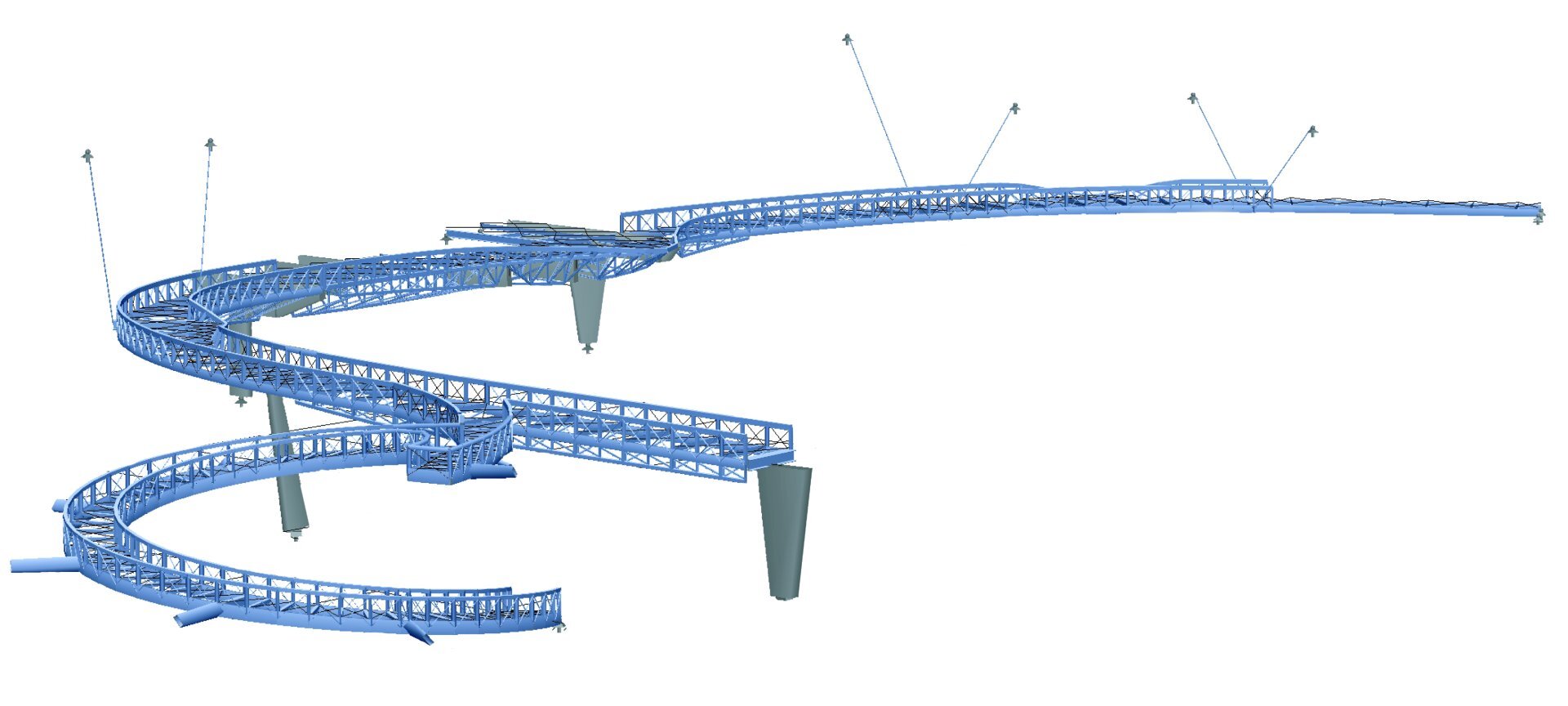

With a length of almost 1001 ft, the Trias bridge in Munich crosses Lerchenauer Straße and connects BMW Welt with the BMW Museum opposite and the world-famous BMW high-rise building.

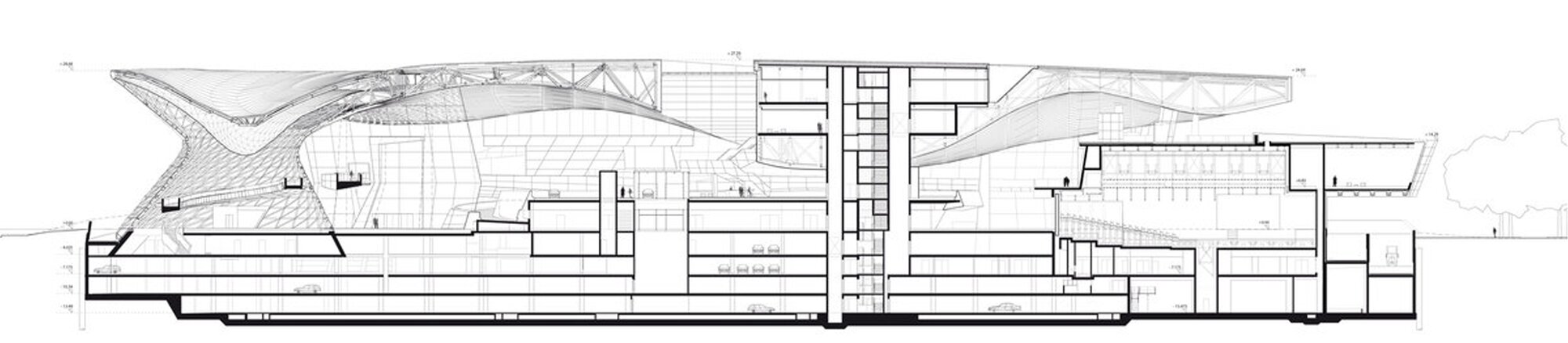

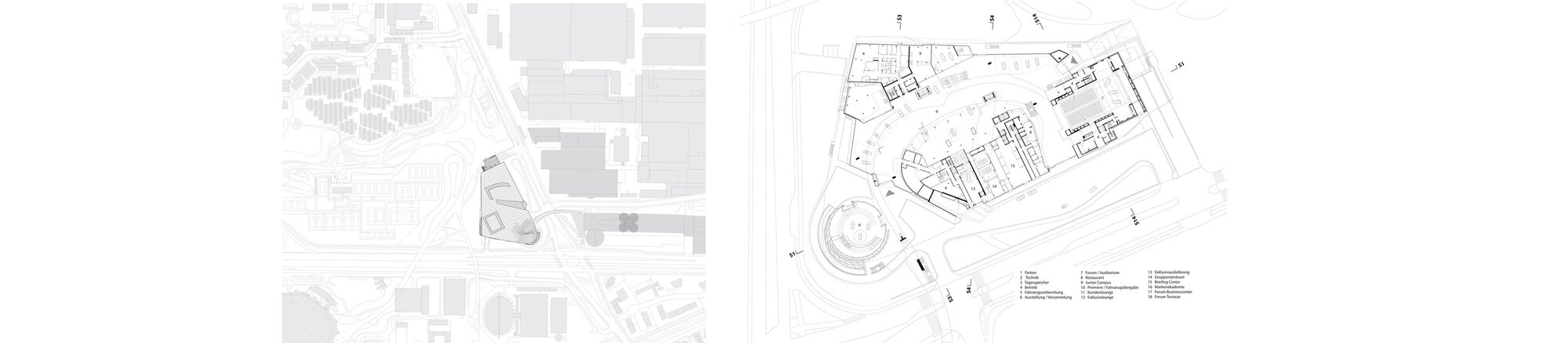

The event and vehicle delivery centre is located in the direct neighbourhood of the Olympic Stadium, the BMW group headquarters and the BMW factory. The building is characterized by flexible and transparent spaces. A striking sign is the double cone placed in front of the complex. The façade consists of a modified mullion and transom system. A kink in the mullions at 7,50 m and further struts at 15 m reduce the free spans, allowing slender mullion sections in relation to the height of the façade.

The roof structure consists of a top and bottom girder grillage with a grid of 5 by 5 m. The top grillage bulges upwards like a cushion. The shape bottom of the layer derives through simulated reactions to the areas below. Both grillages are coupled by intermediate beams to form a three-dimensional framework.

The Production:

First, an aluminum substructure was produced according to CAD data, which also served as a production jig. Using the Kraftformer, we were able to adapt the stainless steel sheets to the contour of the jig. Threaded bolts were then welded onto the back of the sheets to ensure a stable connection to the substructure.

Matt appearance:

In order to meet the surface requirements of the architects and designers, the stainless steel elements were first perfectly aligned. The matt appearance was achieved by blasting the sheets. This process created an even and robust surface.